Cu Paste

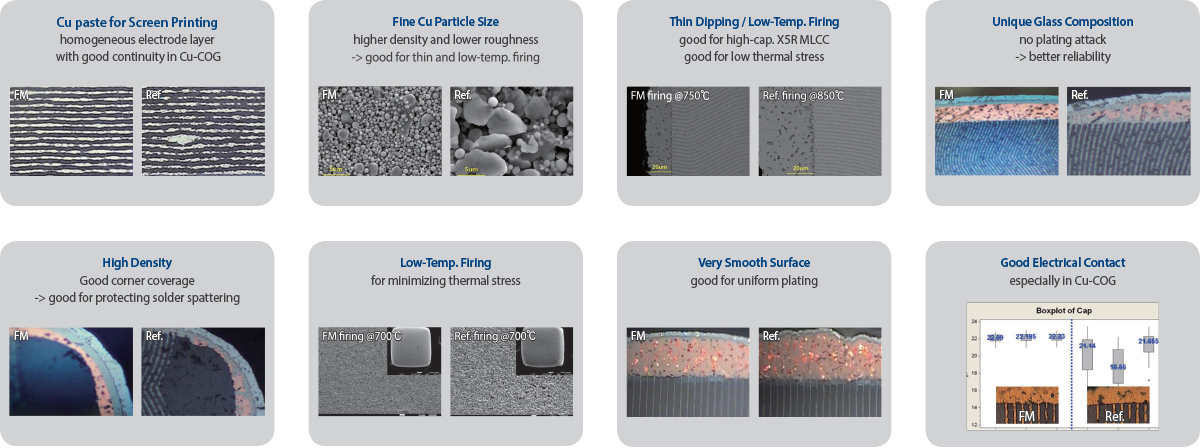

: FCP-L series are Cu pastes for screen printing of inner electrode in Cu-COG (Cu-NPO) MLCC.

They are composed of small and spherical copper and ceramic powders. With FCP-L series, it is possible to make high packing density after printing and good electrode continuity after sintering.

: FCP-F and FCP-S series are Cu pastes for MLCC termination electrode and composed of fine

copper and unique glass powders. These Cu pastes can give high-density termination surface without attack from plating solution, so better MLCC reliability through hermetic sealing. They also can make good electrical contact with low capacitance variation, even at low-temp. firing such as 750℃.

FCP-L series |

FCP-F series |

FCP-S series |

||

Description |

Inner paste for Cu-COG |

Termination paste |

Termination paste |

|

Cu Metal |

Spherical |

Flake / Plate / Spherical |

||

Firing Temperature* |

970 ~ 1030℃ |

800 ~ 850℃ |

700 ~ 780℃ |

|

Metal Content |

40 ~ 50 wt% (controllable) |

65 ~ 80 wt% (controllable) |

||

Glass / Ceramic |

CaZrO3 or others |

F1 / S2 / M5 glass |

||

Viscosity |

10.0 ~ 30.0 Pa·s @10 rpm |

20.0 ~ 50.0 Pa·s @10 rpm |

||

Film Density |

4.5 ~ 5.5 g/cm3 |

3.8 ~ 5.2 g/cm3 |

||

* Firing temperature can be different according to customer’s firing conditions.